Copyright 2022 © Ningbo Xinmadi Automation Technology Co., Ltd. All Rights Reserved.

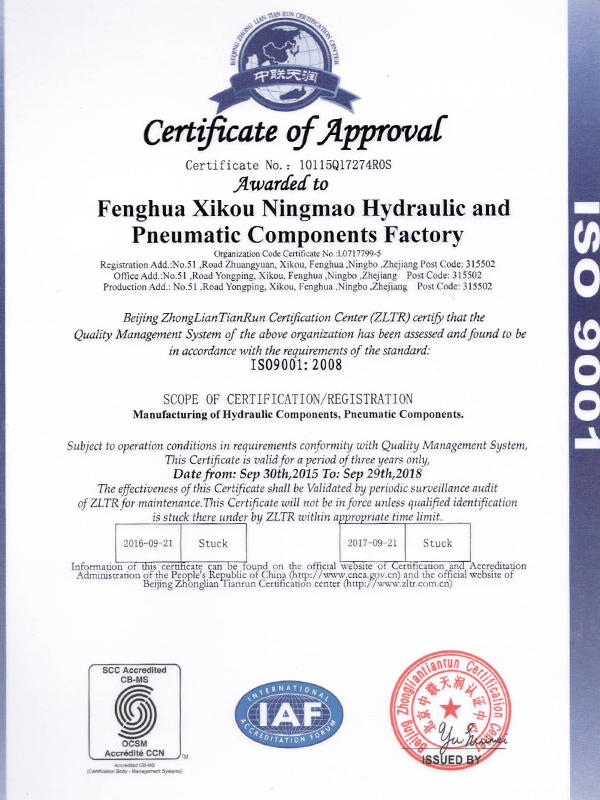

Ningbo Xinmadi Automation Technology Co., Ltd is a China Manual Valves Manufacturers. We specialize in wholesale Manual Valves etc, and have advanced equipment and complete testing facilities to ensure high product quality. The company's main products are pneumatic components, including air source processing units, solenoid valves, cylinders and accessories. Complete product specifications, beautiful appearance, welcomed by customers. As a professional Manual Valves factory, we have a strong R&D team, and can carry out customized design and production according to your requirements to meet your requirements and ensure the quality of the products. It is exported to Southeast Asia, the Middle East, Europe and other regions, and has business outlets in large and medium cities across the country. Very welcome to cooperate with you.

简体中文

简体中文 English

English